Contact

VICTORY TECHNOLOGY

HL: 86-769-8507 7000

Fx: 86-769-8531 3421

Monica: 86-13829137016

86-13925827222

Attn.: Ms Monica

monicachao@xinkeju.com

Add: Dalang Town,Dongguan City,GD.CN.

Special alloy wire Processing equipment

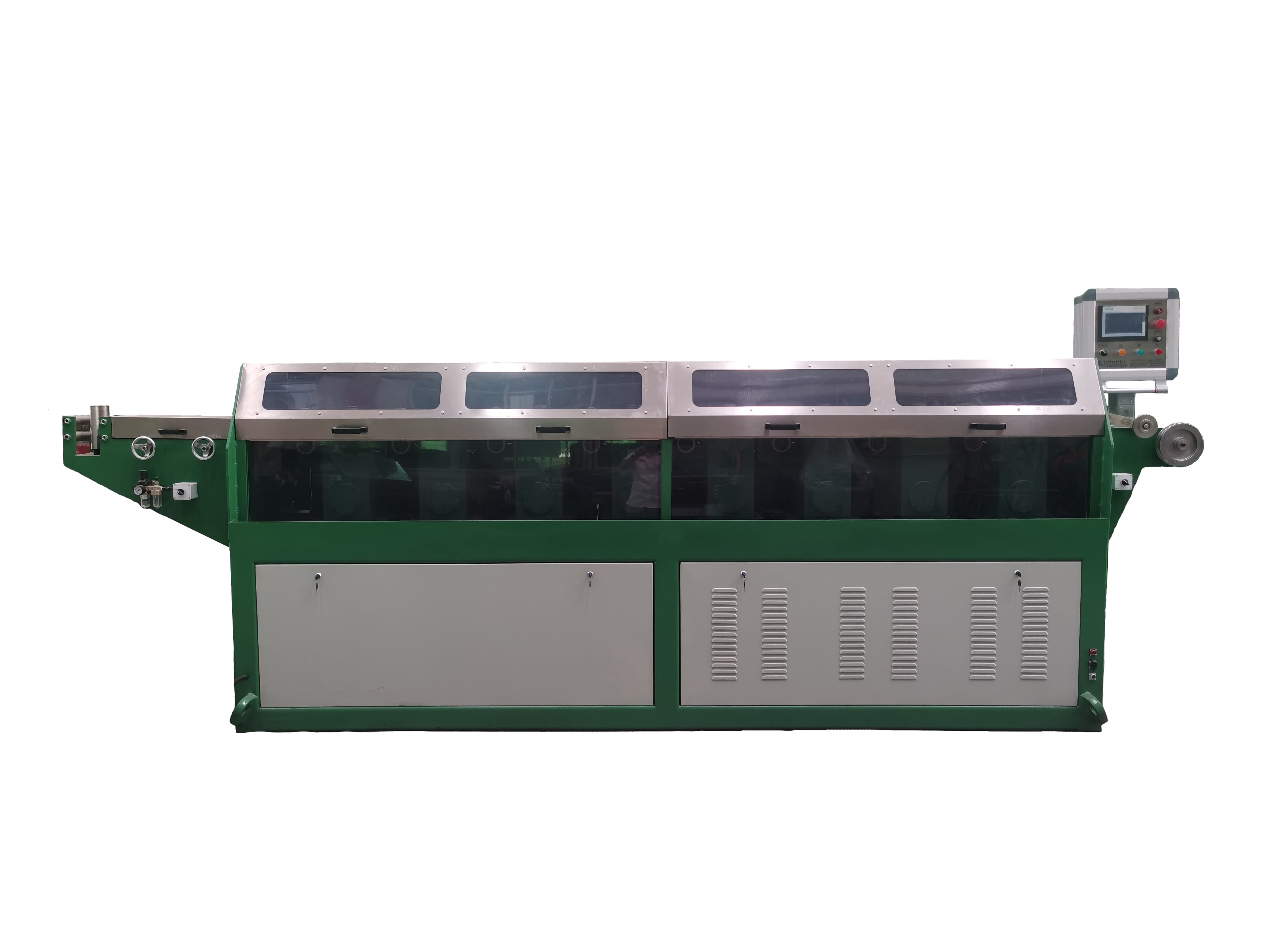

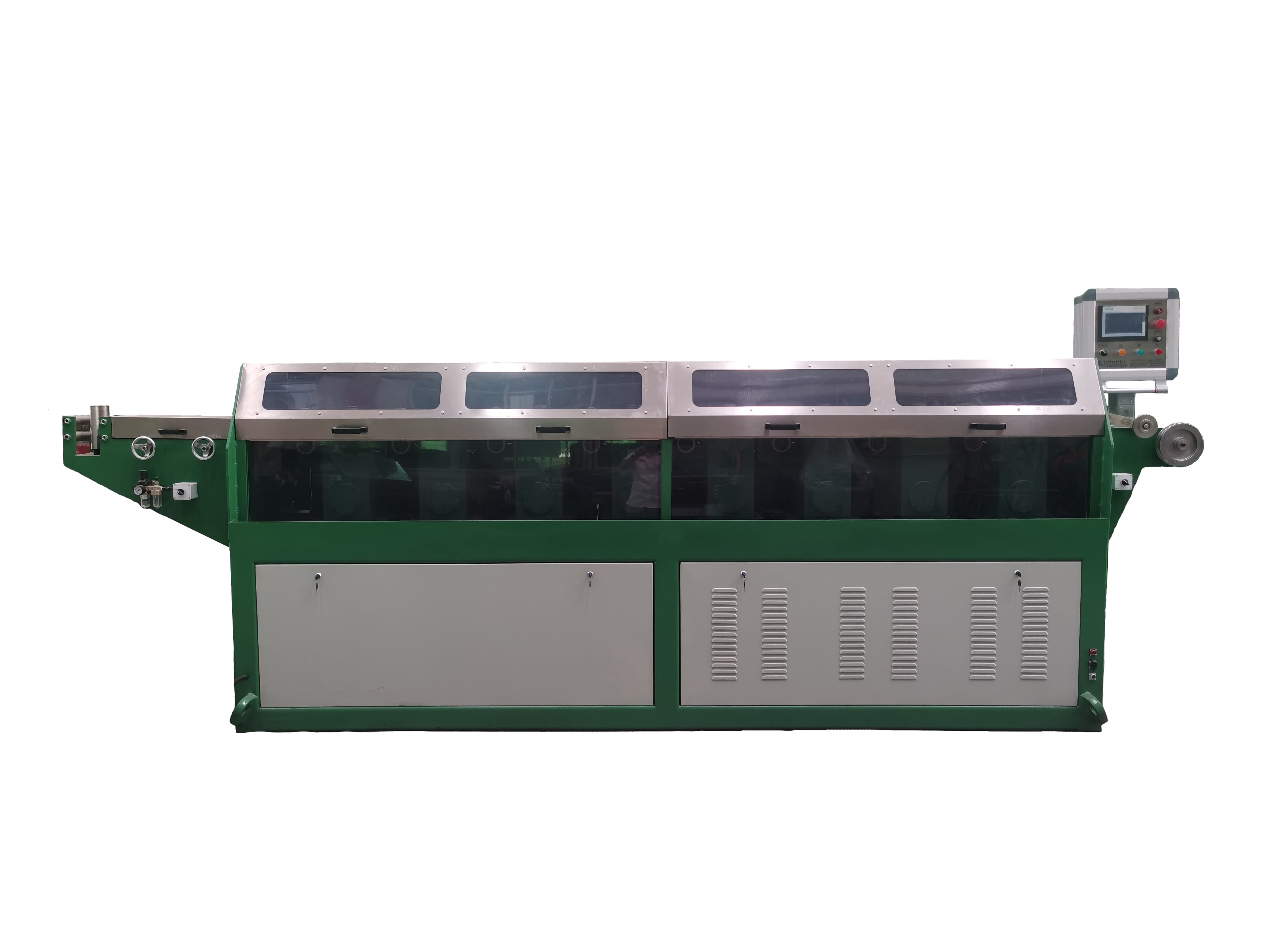

Silver mill

1. technical parameters

Second, the device description:

This model mill is our own research and development, with the advanced technology of our products have obtained national patent office issued a patent certificate, the model is mainly applied to the production of rolled silver wire, widely used in electronics, jewelry industry.

The silver silk mill mainly by the body, straightening wire feed mechanism, rolling body, closing line agencies, cooling and lubrication systems, transmission systems, electronic control part is composed. Combination with steel welded steel body, a small box with cast gearbox. Transmission part adopts helical gears and spiral bevel gear drive, and then roll through the use of special alloy steel heat treatment process management, with ultra-resistant shock, etc., roll form part of the use spray cooling and lubrication. Powered by frequency stepless speed control.

In the body are arranged in parallel with a plurality of roller boxes, each roll box with longitudinal and transverse two pairs of rolls, the two pair of nip roll, respectively horizontal and vertical distribution, the roll after rolling diameter is in proportion to gradually become smaller , the compression ratio is based on the characteristics of the design according to the material extends, each second compression are of equal value, when the wire through the rolls, the material roll is rotating roll, pressure is small wire from the roll after the extrusion, the final The traction device delivered to the closing of the wire trays, achieving wire roll.

Third, the device features

1,Better adaptable: the ability to roll a harder material, is generally rolling mill can not reach.

2, low energy consumption: no need to use eye mode, because the work without drawing dies, reducing the wire through the mold deformation after heat and wire EDM friction heat generated energy; work process is a straight line toward the wire, reducing thread on the tower wheel heat generated by the bending deformation; during the rolling process the slip amount of the wire is small, consumes less wasted effort.

3, Low noise: the traditional tank drawing machine wire drawing process in the tower wheel slip, and wire EDM noise generated through the larger, and during the rolling mill roll wire without jitter, slipping through the rollers is small, the low noise.

4, No need for using the wire drawing dies: simple operation, saving wear-mode time, reduce labor intensity and improve working efficiency.

5, Get the good quality wire rod: after the sequence is not easy to break for late drawing, wire after rolling through denser metal structure will facilitate subsequent processing.

莎车县|

荔浦县|

张家口市|

临夏市|

廊坊市|

绥滨县|

蛟河市|

雅安市|

凤庆县|

大同县|

阜新|

高雄市|

临海市|

闽侯县|

福州市|

景谷|

江孜县|

凯里市|

宁强县|

海南省|

朝阳市|

青河县|

临邑县|

芒康县|

于都县|

专栏|

庄河市|

梁平县|

苗栗县|

富源县|

成武县|

石河子市|

新野县|

乌鲁木齐县|

嵊泗县|

怀化市|

乡宁县|

象州县|

齐河县|

通化市|

邵武市|